Modified bumper molding is widely used in the automotive industry to improve the functionality, appearance, and performance of vehicles. By incorporating design changes or additional materials, modified bumpers offer benefits beyond standard bumpers, including enhanced protection, aesthetics, and aerodynamics.

Impact Absorption and Safety

One of the primary functions of modified bumper molding is to absorb and dissipate energy during collisions. Reinforced sections or added layers reduce the force transferred to the vehicle frame and occupants, improving safety. Some modifications may include specialized materials, such as foam inserts or energy-absorbing polymers, to enhance impact resistance.

Aerodynamic Improvement

Modified bumper molding can also improve a vehicle’s aerodynamic performance. Adjustments to the shape, curves, and air vents reduce drag and improve airflow around the vehicle. Better aerodynamics contributes to fuel efficiency, handling stability, and overall driving performance.

Aesthetic Enhancement

Another key function of modified bumpers is visual improvement. Custom shapes, textures, or finishes allow manufacturers and vehicle owners to differentiate models or add a sporty, modern appearance. Molding modifications can complement the overall design of the vehicle while maintaining functionality.

Accessory Integration

Modified bumper moldings often include provisions for mounting additional components, such as fog lights, sensors, or parking cameras. Integrating these elements into the bumper design improves convenience and functionality without compromising the vehicle’s structural integrity.

https://www.bumpermould.net/product/bumper-mould/plastic-front-bumper-for-bmw-x1.html

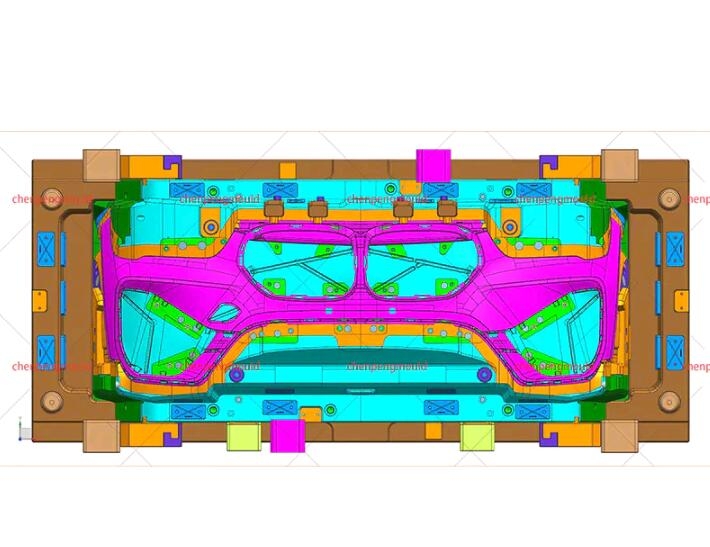

Mould Name BMW X1 Car Front Bumper Chin Mould

Material PP+EPDM

Bumper Size 1900*610*560mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO