Thin wall injection moulding is a specialized manufacturing process used to produce lightweight, precise, and high-volume plastic components. This technology is widely applied in packaging, electronics, and consumer goods.

Lightweight and Material-Efficient Products

A primary characteristic of thin wall injection moulding is its ability to produce lightweight parts with minimal material usage. The process uses thin-walled cavities to create components that are strong yet light, reducing material costs and environmental impact. This feature is especially valuable for packaging applications such as food containers and disposable items.

High Production Speed and Efficiency

Thin wall injection moulding is designed for high-speed production. Advanced injection machines can fill thin cavities rapidly, allowing manufacturers to produce large volumes of parts in a short time. This efficiency supports mass production requirements while maintaining consistent quality and reducing overall manufacturing costs.

Precision and Dimensional Accuracy

Components produced by thin wall injection moulding exhibit high precision and consistent dimensions. The process ensures uniform wall thickness, accurate detailing, and smooth surfaces. This precision is critical for applications where tight tolerances and reliable assembly are required, such as in electronics housings or medical packaging.

Specialized Equipment and Process Control

Thin wall injection moulding requires advanced moulds and machinery capable of high injection pressure and precise temperature control. Proper equipment ensures uniform material flow, reduces defects, and maintains repeatability across production batches. Skilled operation and monitoring are important to achieve optimal results.

https://www.food-container-mold.com/product/disposable-plastic-multi-grid-food-container-mould-series/square-four-gid-box-and-4-1-box-lid-thin-mould.html

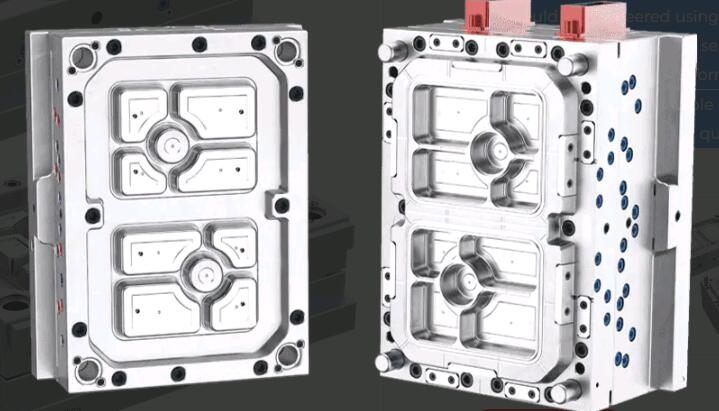

Our Disposable Plastic Disposable Plastic Square Four Grid Box And 4+1 Box & Lid Thin Mould is engineered using cutting-edge technology in high-precision plastic injection molding. This mold series specializes in producing plastic boxes and lids with exceptional sealing performance, ensuring the integrity and freshness of contents. Crafted from durable 2344 material, the product promises longevity and resilience, meeting stringent quality standards.